| Hot cars run better on hot fuel! |

|

| More power, and still getting 24 miles per gallon at 80 mph! |

If you want to use your home-made ethanol in your car as E-85 (85% ethanol and 15% gasoline, before you mix it with gasoline,

it has to be 100% pure: 200 proof. But even though the Charles 803 still will make 194 proof, again and again, you can never

remove that last 3% of water using a still of any kind. You will need to use a molecular sieve. This sounds technical, but

it is real easy. Just read this letter I got from Dr. Grant Carlson with Eco-Rebuilders. "Since we remanufacture old third

generation Corvettes with big horsepower-high compression-fuel injected engines, homemade E85 is important to our customers.

A molecular sieve is just zeolite: link to information about the manufacturer we use is shown here. Buy Type 3A in 10lb bags

(looks like a small pea gravel) it is only a couple of bucks and it works very well to dehydrate the ethanol. We mix about

5lbs in a 5 gallon can and let it sit with the ethanol overnight and pour the dehydrated ethanol through a screen, into another

can the next day. To get the water out of the zeolite we just broil it on the backyard grill - it is reusable indefinitely.

http://www.thomasregister.com/olc/adcoa/molecula.htm

The basic dilemma for converting engines over to a new fuel is like the question, Which came first, the chicken

or the egg?

If you convert your car to run only on alcohol, where will you buy it when you run out? When will anyone supply alcohol fuel if there arent any cars converted to run on it?

In 1980, Brazil neatly solved both problems at once, along with their problem of really low prices

on the world sugar market. So the military government declared that the countrys sugar cane production would go into

making alcohol for fuel, and the car manufacturing companies in Brazil will have to make cars that run on alcohol.

The result? Twenty years later, alcohol fuel is much cheaper and much more available than petrol. When

you rent a car at the airport, you have a choice between clean and cheap ethanol or a dirty and more expensive petrol

fueled car. Ethanol will cost you about $2.50/gallon, while gasoline will cost $4.20/gallon.

Because of the successful and widespread use of alcohol fuel in Brazil, most manufacturers now make cars that are fuel injected,

and this is controlled by a computer chip that can be changed out to make it into an FFV (flexible fuel vehicle.

| High proof still with automatic control valve |

|

| Controlling temperature is the key to consistant high proof. |

How to Make 200 Proof:

Corn grits, the laboratory process:

To make 200 proof, you first make yourself some 180 to 190

proof, and you can make 190 proof (95% ethanol) successfully, time after time with the Charles 803 still. See Principles of Operation.

Now here is one way to get out that last 5% of water, which cannot be done with a still. (Warning, this is a bit technical:

the Zeolyte process described higher up on this page is much, much easier).

If there's ethanol in the gas you buy at your local filling station,

there's a slight chance that it was filtered through corn grits, using a technique developed at Purdue University. When the

corn grits get saturated with water you just make more ethanol out of them! Drying of ethanol refers to the process of removing

the last 5 or 10% of water, in order to make anhydrous, or "neat" alcohol.

Ladisch and his students at Purdue University

found that drying of ethanol vapors saved energy and was economic. The corn industry makes ethanol by fermentation and has

lots of corn grits readily available. Passing the wet vapors through a filter bed of corn grits or other drying agents removes

most of the water to yield a product that is close enough to absolute ethanol. When the drying agent approaches exhaustion,

it is regenerated by heating and reused. Eventually the drying agent breaks down but has potential uses elsewhere in corn

processing.

Source: Mike Ladisch; ladisch@ecn.purdue.edu

Octane, fuel mixes, and 180 proof:

180 proof ethanol is considered to be rated at about 105 octane. Anhydrous alcohol, is around 110 octane,

which is why only a small amount, about 10%, has to be mixed with gasoline to increase the rating. The Indianapolis

500 race in May of every year has used straight ethanol as their primary racing fuels for over 80 years, and this is still

the case. Alcohol has a lot of power, and it burns cooler, which is really great for a race car, since heat is a big enemy

of engines, along with friction. The only danger of alcohol as a racing fuel is that when there is a big car wreck, the flames

are pretty much invisible, so a driver can be on fire and no one will see it. Of course, now they all wear non-flammable jumpsuits.

My point, however, is that in the racing industry, ethanol has a long history of being the preferred fuel. The guy who helped

us teach the car conversion class used to say, "I just want to learn to make my own ethanol because I like to race cars, and

the stuff is expensive."

Ethanol was also the fuel of choice for aviation fuel during World War II for both the Americans and the Germans.

Octane is a strange rating system, as they don't really count

the number of octal hydrocarbons as they do when they name methane (4), propane (3), or butane, (C4H10). Octane would be,

naturally, 8. But rather than measuring a percentage of octal hydrocarbons, octane is an index of how slowly a fuel burns.

The slower, the better, so that the explosion of the fuel/oxygen mixture can push the piston down rather than slam it down.

That is what happens when you use too low an octane fuel, say, 85 octane instead of 90, and you hear that annoying knock or

pinging sound. Too make matters worse, back in the late 70's, the petrochemical boys decided to change the octane rating numbers,

so that what they labelled at 90 octane was equivalent to say, 86 or 88 octane from the previous system. In other words, they changed the numbers so they could sell us a cheaper grade of gas for the same amount of money we used to pay for a higher grade.

Back in the 60's, the USA manufacturers made mostly big muscle cars, and it was common to buy big V-8 engines

that had 300 horsepower, and got about 8 or 10 miles to the gallon. These engines were high compression, with compression

ratios of around 12 to 1, which is perfect for ethanol. When I first started

high school in 1963, and drove a motorcycle to school, gas was only $0.34 per gallon, for regular, and $0.38 for what they

called ethyl or premium grade, which was 98 octane. This was first lowered so that premium was only 94 octane,

and now it is only 90 or 92 octane, depending on what country you live in, while regular is only 85 to 87 octane.

The automotive industry had full advance knowledge of the changes in the octane rating system, since

many member of the Board of Directors for General Motors and Ford also sat on Exxon and Union Oil Boards. So the automotive

industry powered down their cars, and they advanced the timing a bit more, to compensate for the lower grade fuel. This was

back when they added lead to the petrol (which they still do in China), to reduce octane. Lead is cheaper than alcohol or

MTBE, but much more hazardous to health.

In the early 80s, the

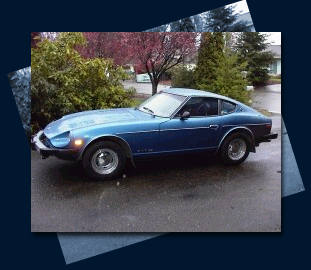

US public discovered the better mileage of Japanese built cars, with their smaller engines and higher RPMs, so the

US automotive industry went into a huge slump, and Toyota and Datsun (now Nissan) became one of the most popular cars in the

world.

A real complete ethanol conversion, according to our racing

car specialist, in addition to drilling out the carburetor jets and replacing all plastic and rubber gaskets in the carburetor

with one which would not dissolve in ETOH. (Paper gaskets worked fine.) It also meant changing out the pistons for hemispherical

racing pistons, and shaving the heads to reduce the cylinder volume and thus increase compression.

Later cars were manufactured to handle this lower grade fuel.

The term gasohol, used throughout the USA in the early 80's, was a mix of 10% anhydrous (without water) grain alcohol. Arco

(Atlantic Richfield) was one of the first to use this mix to up the octane on their petrol, and they bought a sugar cane processing

plant in Louisiana and started making their own alcohol. It allowed them to eliminate the lead, hence the term, unleaded. Soon the big 5 oil companies all had ethanol distillation plants in the Southern US,

and I believe they all still do. The authoritative history of ethanol production and use is to be found in back issues of

Gasohol, USA, published by Charles Walters, Jr., at Box 9547 , Kansas City, Missouri, 64133. I do not know if this address

still works, but it has been years since this magazine went out of business. This same publisher still publishes Acres, USA.

I recently recommended this magazine to an organic farmer, and she was delighted to find that they have a whole

library of books available. They may still sell a book which Charles Walters

wrote on ethanol. Anyway, all of the above is but a tailgate view of automotive history from the viewpoint of an

old farmer (I grew up on a dairy farm, and also kept bees for over 20 years).

In terms of lubrication, there are several manufacturers who make what they call, synthetic oil. Now, what this really is, my former contacts in the oil industry tell me, is biodiesal! It is vegetable

oil which is has been converted into certain ethyl esters with the addition of 10% anhydrous grain alcohol, i.e., ethanol.

Amsoil was the first to come out with this, and it sold for 5 to 6 times the price of a quart of oil, but part of the high

price was due to the fact that they decided the best way to reach the market was by word of mouth, of people using this, themselves.

So they started a multi-level marketing organization, like Amway, to sell it. Later, Mobil came out with Mobil One, then Castrol

offered a synthetic oil, and now most oil companies have a synthetic oil which they claim can go 20,000 miles between oil

changes (instead of the usual 3,000 to 5,000 miles).

I recently talked with a Porsche salesman, and their

dealership sells all brand new Porches (we are talking cars in the ($70 to 80,000 price range, with a top speed of 180 miles

per hour, with synthetic oil in the engine! Then they brag that these cars only need an oil change once every 15,000 miles. These cars are made to be able to sustain cruising speeds of 120 to 140 miles per

hour on the German Autobahn, and the factory backs them up on this synthetic oil, so you know it is good stuff! One of the

main reasons that this oil last longer is that it is less susceptible to oxidation, which is one of the things that changes

the composition of regular oil. Second, it provides superior lubrication because the molecules are much smaller, thus, slipperier.

The one question I never got answered, however, is, if you drive a car on ethanol fuel, it seems

to me that the synthetic oil would degrade a bit faster due to small amounts of blow-by, which is what you call it when small

amounts of burning gases make it past the piston rings, going the reverse direction of where you want them to go. Ethanol

is too good a solvent, sometimes. This would dilute the oil a bit more, I believe, but I do not know the overall effect of

this. I always used regular 30-W or 10-30W oil, and had no problems whatsoever on the lubrication side. I just had to

change my fuel filter every time I changed oil, as I picked up a bit of rust form the gas tank.

To build your own 180 proof still, order the blueprints with very clearly written, easy to follow instructions with photos.

Click on the Paypal button, above, to send $30.00 via Visa or Mastercard.

|

|

|

|

|

|

|

|

|

How pure do you want (or need) it?

OK, you can find a lot of discussion on

the Web about making 190-proof pure grain alcohol. These discussions are mostly for home distiller enthusiasts who are only

thinking in terms of making drinking alcohol. Naturally, if you are going to drink it, you want to make sure it is free from

any small amounts of poisonous byproducts like methanol and fusil oils, as well as any traces of heavy metals like lead or

mercury. But when you are burning it in your engine, anything that contributes to combustion should be left in, really. So there is no need to do any fine filtering, other than a paper filter like a coffee

filter (for small amounts) or an in-line paper cartridge water filter for larger amounts. All you need to do is make sure

there arent any particles which could clog your carburetor or fuel injectors.

Next, in terms of proof, how high

does it need to be? You are never going to make 200 proof alcohol in a still, because you always come up against a physical

limitation which has to do with the concentration of vaporized ethanol molecules at a specific temperature. This is known

as the azeotropic equilibrium barrier, and is beyond the scope of this article.

So 190 to 192 proof is as high as you can make with any still, no matter how efficient it is. To get the last 5% of

water out of the ethanol can require just as much energy as it did to get out the first 95%. But it can be filtered out through

corn grits (see the link on this page) to make 100 % anhydrous alcohol.

Now, you don't need anhydrous alcohol unless

you intend to mix it with gasoline (petrol). You may want to do this for the simple reason that you wouldn't have to

do very much in the way of converting your engine, as you can make your own E-85.

E-85 is, as you might guess, 85% ethanol and 15% gasoline (plus some anti-corrosion

additive). This is quite differnt than a product sold in the 1980s, called Gasohol, which was gasoline with 10% ethanol.

This name confused people, and they didn't know if they could use it or not, even though it would work in any engine.

So they went over to calling it "Unleaded Premium". This is a pretty good way

to extend your gas mileage and also is a pretty safe way to use alcohol as a fuel, for the simple reason that if you ever run out of your home-made gasohol, you can mix it with unleaded gasoline. Then you are

back on the road again. But the only kind of alcohol which will mix with gasoline (petrol) is 100% (200 proof) ethanol. If

you have any water content in your home-made ethanol, it will separate out once you mix it with petrol. Water is heavier than

gasoline, so it forms a thin layer at the bottom of the fuel tank of you car, and then gets sucked up by your fuel pump and

your engine will cough and die. This isn't the end of the world, as you can get it removed by adding a bit of methanol to

your tank (it is sold as "Gas Dryer" or various other winterizing products at automotive parts stores).

Now for those of us who like to run on pure

alcohol which has no nasty petrol mixed in with it, then 160 to 170 proof is plenty high enough. You can

get great mileage on this if you do a full conversion to alcohol, but you will be out of luck if you run out of fuel, unless

you make your car a duel-fuel vehicle (which many people did back in the early 1980s, by installing a duel carburetor setup.)

See my Web pages, Going Down the Road.

You do not have to try to do anything different

to get your 190 proof, (95% ethanol) other than to closely monitor the temperature setting of the automatic control valve.

You may have to do an elevation correction (if you are living in the mountains) to make sure you know precisely what temperature

to set it at, but the overall idea is that the top area of the reflux column, just before the vapors rise into the condenser

section, must be controlled at precisely 2 degrees F above the condensation point of alcohol which is 174 F. Then you have

pure alcohol moving up, and the condensed water never goes any higher. This is

thoroughly explained on my web page, Principles of Operation.

The automatic control valve I use is a thermostatic water valve, which opens on temperature

rise. You will never get the precise control you require from trying to control the rate the water boils with an electric

heating element. That is like cooking on an electric stove. The big problem is that the pot always boils over, right? Wouldn't

you rather cook with gas? Furthermore, you are much less likely to burn your

mash if you have any particulates that come out of solution in the wash, even after it has been filtered. You have sugar,

therefore you have carbon. You know what it is like to clean out a blackened stainless steel cooking pot. You don't want that

burned taste to get into subsequent batches, so better to cook with gas, and also better to use a reflux column like mine

which can precisely control the temperature inside the reflux column on a graduated basis, so that you have a reverse heat

flow going on inside the reflux column. Trying to control temperature at the condenser section is like closing the barn door

after the horses have escaped. This still design was built by myself and a group

of a dozen people, including three engineers. We refined the design with four different generations of successive models.

This still is as different from the tabletop pot stills as a new Lexus is from a '57 Chevy. Those early models have their

charm, but to make enough to be used as a fuel, you want some serious production.

Read my explanation of how this still works, in Principles of Operation, as well as the chapter on Safety and Boiler operations. People who buy my still plans will also get a chapter on How to handle high volumes of mash and fluid handling.

I

have produced well over a thousand gallons of high proof alcohol in the many different stills I have built over the past twenty

years. Sure, my intention was and continues to be using ethanol for fuel, but the principals are the same. I can and have

produced 195 proof on my first run, it is just that when I am talking about 180 proof in my web pages, it is because this

is a more efficient fuel in terms of getting more miles per gallon when you are replacing gas with homemade brew in your tank.

In fact, you get better mileage than you would on gas. I sell the blueprints

for my still, just go to my Contact Us page for info on this. Also, I sell the temperature control valve for $290. I have looked for years, and haven't found

anything better than what I have been using all along. You can see the valve on the left side of this photo, on the left side

of this page. Also, once you buy the plans and build the still, I am happy to

be available to answer all your question via email.

robertwarren@mail.com

Rule 1: Gas and water don't mix!

Rule 2. High tuning for high performance.

Rule 3. Carry an extra can!

Water and gas don't mix.

This means you have to decide whether to convert your car to run on homemade high proof (then you are truely independant

from relying on nasty and greedy oil companies like Esso/Exxon. ) For the best performance, you will need to

change the size of your jets in yor carbuerator (if you have one) or the fuel/air mix of the elctronic fuel injectors. You

would also want to up the compression ratio to 12 to 1 by installing racing pistons. Finally, you may need to actually install

a separate fuel tank so that if you want to switch between petrol and alcohol fuel, you can do this with a bypass valve/switch,

without having to drain the tank. If you have a little bit of 180 proof in the bottom of your tank and add petrol, the water

in the alcohol will separate out and sink to the bottom. To get it out without draining the tank, you have to add either some

100% alcohol or better, some methanol (which is sold as a de-icer in automotive parts stores).

High tuning for high performance:

Up the compression ratio, change your fuel jets, advance your timing until it runs really smooth, and watch for

cops in your rear view mirror!

Carry an extra can!

If you change over to home-made fuel, carry enough to get you home again. Henry Ford built the Model T to run on

either gas or alcohol, because "There are more stills in this country than gas stations!"We used to be able to buy alcohol

back in the 1920's, until Standard Oil of Pennsylvania started the "gas wars" by selling gas at $0.05/gallon for just long

enough to run the "Alky sellers" out of business.

The 4 Myths about Alcohol Fuel

My basic philosophy when it comes to petroleum is, don't trust the oil companies! Now, I usually buy gas just like

everyone else, but having had the freedom of being able to make my own fuel, and finding that I got great performance on it,

I did a bit of digging to see what the truth was behind the myths that the oil iindustry was putting out.

The 4 basic myths propagated by the petrochemical industry are:

1. Ethanol doesn't have as much energy as gasoline. 86,000 BTU's vs. 126,000 BTU's.

Answer: Burning it in an open flame to boil water is not the same as burning it in an internal combustion engine.

Ethanol burns slower which is better for transfering power to the piston. It is a well know fact that only 14 to 18% of the

energy in gasoline is used effectively, as most of it is lost in heat, as well as some unburned emisions. I have been

able to get the same mileage out of 180 proof as I did with unleaded. If you start using E-85, you will get about 10 to 15

% less mileage, but pay about 20% less per gallon of fuel. If you modify your engine to optimize it for this high octane

106-fuel, your mileage will be the same as on gasoline.

2. Ethanol takes more energy to make than you get out of it.

Not true. This is some very old propaganda. modern commericial distilleries making 40 gallons per year each are usually

only using about one-third the BTU value of the final 200 proof Ethanol product they are selling. See my web page, " More or less energy" 3. Ethanol is highly corrosive.

This is nothing that can't be solved with a modern understanding of coatings, gasket materials, adhesives, and fuel additives

In fact, VW, GM, Ford and many other companies have made ethanol fuel cars designed to run on alcohol. The

other issue is that E85, which is 85% anhydrous alcohol and 15% gasoline has corrosion inhibitors to enable this

fuel to be sold on the open market (about 15 states in the midwest sell this fuel).

4. Ethanol is high in emmisions.

The reverse is true. See the Clean cities website. http://www.eere.energy.gov/vehiclesandfuels/epact/

|

|

| High compression engines work best on ethanol. |

Click here for a fairly comprehensive report on the net energy gain in commercial alcohol production. Written in 1997, it

gives detailed information on emmisions and reduction of greenhouse gases. Page 11 concludes that cars using E85 will have

50 to 60% reductions in fossil fuel emmisision (even though they are including the fossil energy use in growing, transporting,

grinding, cooking, and distilling the corn into ethanol)!

|

|

|

|

|