The AAN 20 valve five cylinder turbo engine is related to the 3B 20 valve five cylinder turbo engine that Europe and the US got in the early S2 coupe (Europe) and the 200 20vt (Europe and US but not Canada).

One of the fundamental differences between these two similar but different engines is the ignition system. The 3B used a hall sensor-equipped distributor and a single coil. The AAN uses five coil-on-plug (COP) (PN 034 905 101) coils and two three channel (PN 4A0 905 351A) power output stages (POSs). The ECU controlled the ignition via the POSs and inputs from a cam position sensor, a crank position sensor, an engine speed sensor and a manifold absolute pressure sensor, among other things.

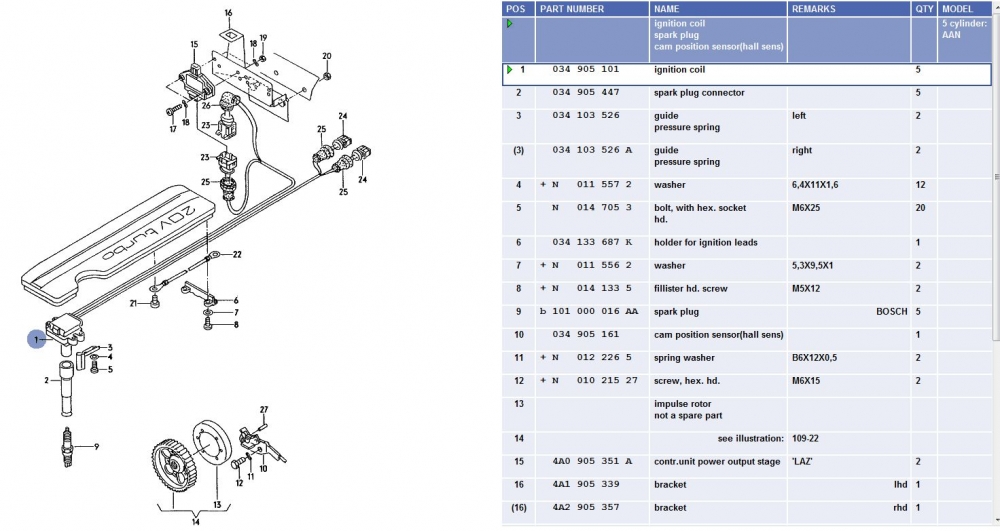

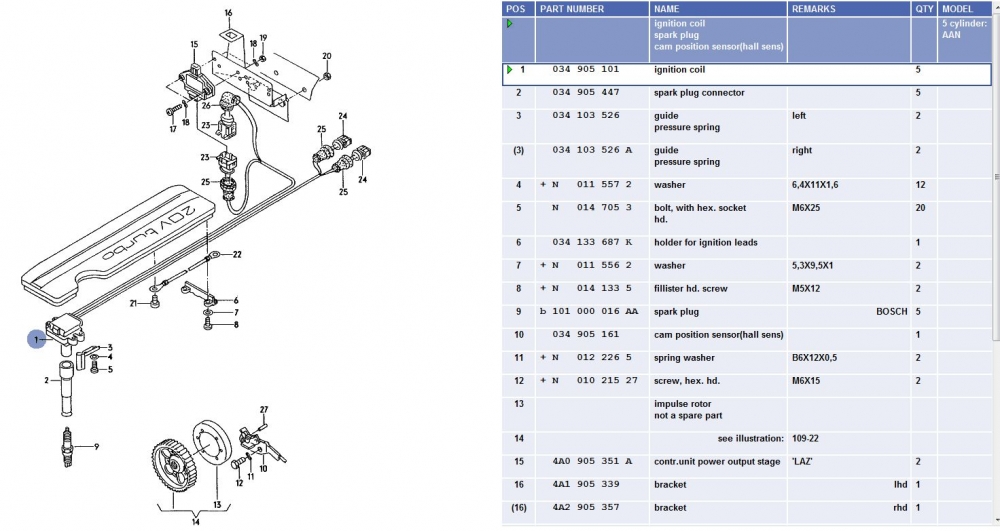

The PNs for our ignition system are:

Coils = 034905101 (Item 1 below)

Coil to plug connector (boot, tube) = 034905447 (Item 2 below)

Cam Position Sensor = 034905161 (Item 10 below)

Power Output Stage = 4A0905351A (Item 15 below)

Here is a link to the various ECU inputs and outputs that are involved with the AAN ignition (if you are curious):

AAN Motronic ECU inputs and outputs

Most of our AAN (and all ABY and ADU) engines have the G40 cam position sensor located behind the exhaust cam sprocket. If the cam position sensor fails, the engine will not restart, as explained here:

Link to Info about the G40 Cam Position Sensor

One slight quirk is the early AANs (to about Feb 92 build dates) had their "cam position sensor" (Hall effect sender) in a vestigial "tuna can" distributor located under the intake manifold, near the firewall end of the block, as shown in this post:

Link to early AAN "Tuna Can" Hall sender info

The AAN ignition system has generally proven to be very robust and, in addition to allowing an increase in horsepower and torque over the 3B (e.g. stock 227 hp AAN vs 217 hp for the 3B), it also eliminated the nasty "spark hop" problem that occurs in high hp 3B engines (especially when the wrong (wide) rotor is used (instead of the proper narrow 3B rotor). That said the AAN ignition does suffer failures of the cam position sensor, the POSs and the coils.

To replace the OE ignition system, you will find the "351A" POSs run around $200 each and coils run around $125 each (e.g. Kingsborne). Coil to plug boots are around $5 to $25, depending on your source. As a result, a complete OE AAN ignition replacement would cost over $1000. The upside is it would likely be good for 100K miles or so.

One of the weak points of the AAN ignition is the power output stages (POSs). They are basically transistor-based switches and, as such, fail in a number of different ways. Here is some POS info, originally from Sept. 2005, but updates since then:

POS info including how to swap pins to gain use of the spare channel

As these engines age, their ignition components start to fail, e.g. brittle wiring, heat failures, etc. At that point, you will start to experience missing or hesitation. You can track down the problem (most likely a dead POS channel or a weak coil) using this procedure:

Link to a missing and hesitation diagnostic procedure

Based on the failing POSs that result in missing and failing coils that also result in missing, in the summer of 2005, I decided that I wanted to develop an alternative to the OE AAN ignition system, just so there was one. I decided to use the 1.8t coil packs (even though I knew that they had been the subject of a recall). I went ahead with this in Aug/September 2005 and "published" a DIY in early October 2005:

Link to the original 1.8t coilpack DIY (also available as a pdf on S-cars.org)

From the get-go, I personally made no claims about increased performance or freedom from failures.

The 1.8t coil pack conversion concept was subsequently commercialized by 034 and Apikol in April 2006. I don't recall what claims they may have made. I do know there were coilpack failures. (The 1.8t type coil packs don't like high heat, especially as a result of tracking (sustained high RPMs)).

One of the options in that time frame was 034s "High Output" coil-near-plug (CNP)system based on coils that are proprietary to them. The coils are very similar in appearance to some Mercury Marine coils:

Link to an interesting coil photo

Sometime in the summer of 2008, a few people (450exc115 and lloyd21) were developing an ignition conversion using Corvette style LS2 coil-near-plug coils, using info from my 1.8t coilpack DIY and an RX-7 website. I consolidated that info and posted to AW and the S-car-list in July 2008:

Link to an early quasi DIY for the D585 coils

Since then, a number of people have done this conversion using the more robust D585 LS2-style (Yukon and Silverado truck) coils that have heat sinks/dissipaters. Chris C. (fastscirroco), kinderutz, and lloyd21 (Charles L) are but a few. The wiring is pretty straight forward. The brackets and mounting locations (typically on the stress bar, away from the turbo) are the differentiators of the DIY-ers.

Here is lloyd21's bracket for the similar D581 coil pack:

Link to lloyd21's D581 coil bracket photos

Here are some DIY pricing comments from Chris C.:

Link to Chris C (fastscirroco's) pricing summary

Here is a link to a current (May 8/08) D585 ebay "auction":

Link to a D585 coil "auction"

In the meantime, Marc Swanson has developed a complete plug and play kit based on the D585 coils. While the price is higher than the DIY version, it's high quality and only takes about 30 to 45 min to complete, start to finish. As bonus, if you want to, you can run the "20V Turbo" OE coil pack cover (you need to remove the OE coils of course).

Previously, I have steered people to Apikol's 1.8t coil pack plug and play kit. Everybody commented back to me that they were happy. Some had the odd coil pack problem. Recent "investigations" involve using the latest S4 V8 coil packs (but even they aren't bullet proof).

Recently, I have steered several UrS owners to Marc's D585 kit and those that have purchased Marc's kit are all very happy.

Nobody has reported the success of using these D585 coils in a tracking situation (yet).

Hope that wasn't too boring.

Dave F.