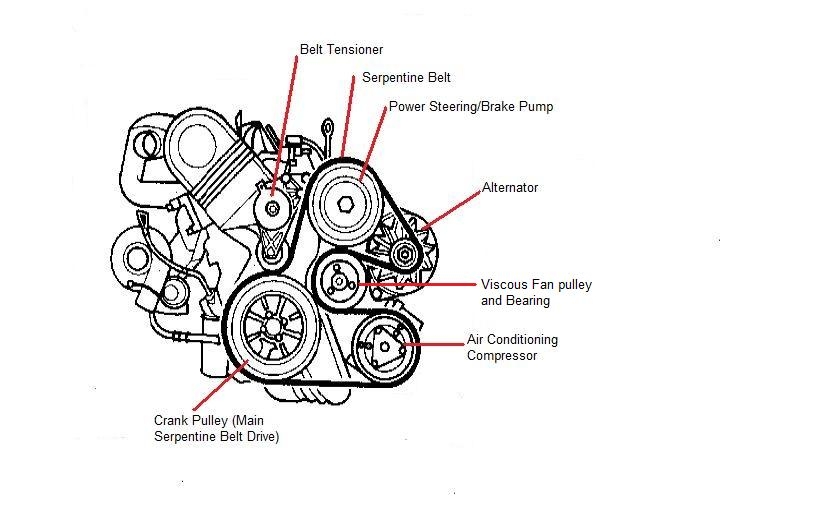

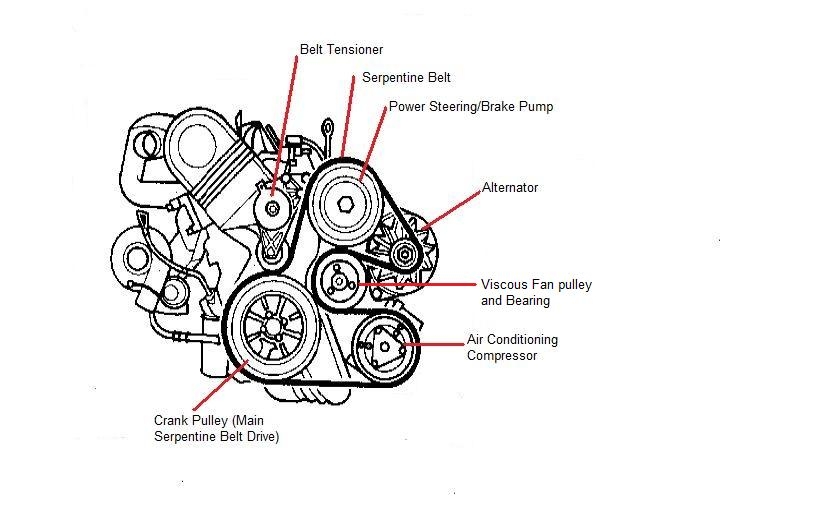

Our AAN engines use a ribbed serpentine belt to drive the engine accessories, e.g. power steering pump,

viscous clutch fan, alternator and air conditioning compressor. However, since the power steering pump also creates the boost pressure for our braking system, if the serpentine belt breaks, then you loose power steering, power brakes, air con and the alternator. What is worse is if the serpentine belt breaks and shreds, some of the serpentine belt "Strings" can wrap around the lower cam drive pulley (at the crank), causing the cam belt to jam and break. Since this stops the cams from moving but not the pistons, this causes the pistons to whack into the intake valves because they are no longer getting out of the way. Therefore, it is important to replace the serpentine belt when it first starts to

crack or starts to squeal

The tension in the belt is maintained by a spring-loaded serpentine belt tensioner. These normally do NOT fail, but it has happened (to me, for example). In this case, its the equivalent to a belt failure (but more costly).

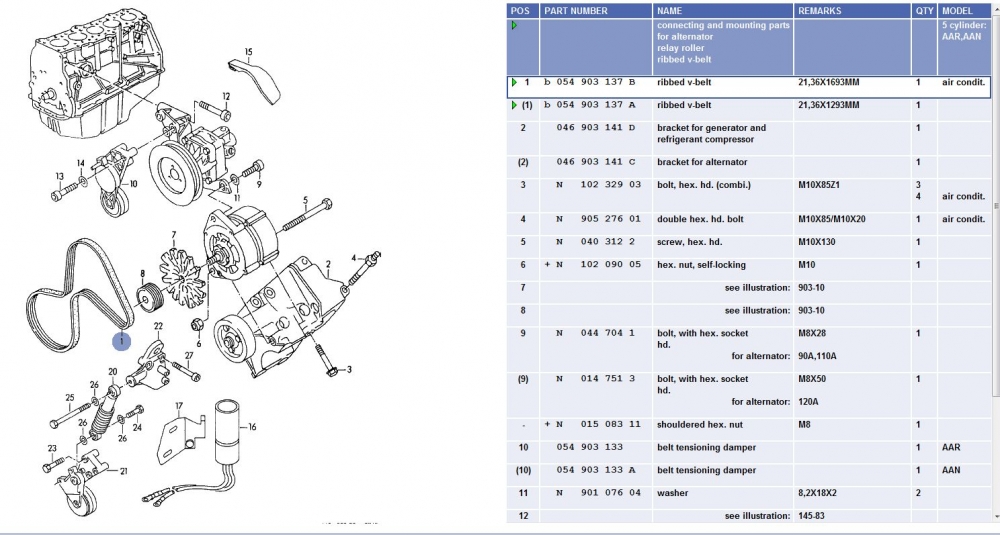

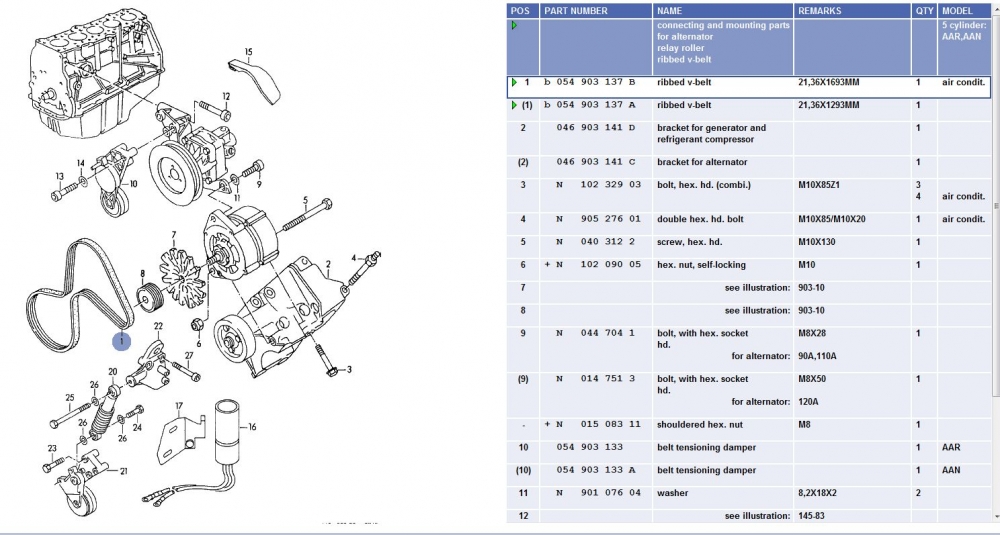

The PNs are Belt = 054903137B, tensioner = 054903133A, belt cover (item 15)= 054903123B, as shown here:

To replace the serpentine belt, you first need to take the tension out of the belt by rotating the serpentine belt tensioner with a 17 mm wrench as shown, and place a pin or bolt through the two holes to lock the tensioner open. (Images courtesy of Nate P. (ImQuattro) from his

cam position sensor replacement DIY)

You can probably replace the serpentine belt without removing the belt tensioner but I *think* it is easier to remove it since you can see better what is going on.

With the tension out of the belt, remove it from the drive pulleys, noting how it is routed as you remove it. To install the new one, the belt "flow" path is as shown here in bold black:

I didn't have a proper serpentine belt tool (long flat bar with a pin to help you loop the belt around the driven devices). However, I was able to get everything in place by starting with the air conditioning and idle pulley loop, followed by the alternator and power steering pump, leaving the crank pulley for the very last. The the tensioner was reinstalled and the tensioner unlocked (slowly) to add the tension back in. 30 min job if you have the tools (17 mm wrench and 6 mm allen wrench/socket). Way easier than messing with a damaged head from a broken serpentine belt jamming the cam belt.

You might get squealing from something rotating at the front of the engine sometime. This could be a number of things including the cam belt tensioner pulley or water pump or any of the items driven by the serpentine belt (the serp belt pulley, power steering pump, alternator, viscous fan pulley, or the air conditioning compressor). The first step in finding the problem is stopping the engine and releasing the tension on the serpentine belt (see above). Now start the engine. If the squeal is still there it is the cam belt tensioner pulley or water pump (sorry, you are now into a big job). If everything is quiet, then it is one of the devices driven by the serpentine belt. You need to spin them one by one to see if you can find the problem. The two most likely suspects are the serpentine belt tensioner pulley bearing and the viscous clutch pulley bearing.

If the serpentine belt tensioner pulley bearing starts to make noise, you either need to buy a complete tensioner OR try to replace the bearing in the pulley.

Fred Munro's Serp Belt Tensioner Bearing R&R DIY suggested using a NTN 6203 LH (or LHA) bearing (about $26). However, recently some people have used a NAPA SKF bearing 6203-2RSJ which is an alternator bearing (should be up to the same heat characteristics as the NLA bearing). Price at NAPA is around $10.

If the problem seems to be the viscous fan pulley bearing, then you need to replace the bearing.

HERE is info on doing that.

This could be on the exam.