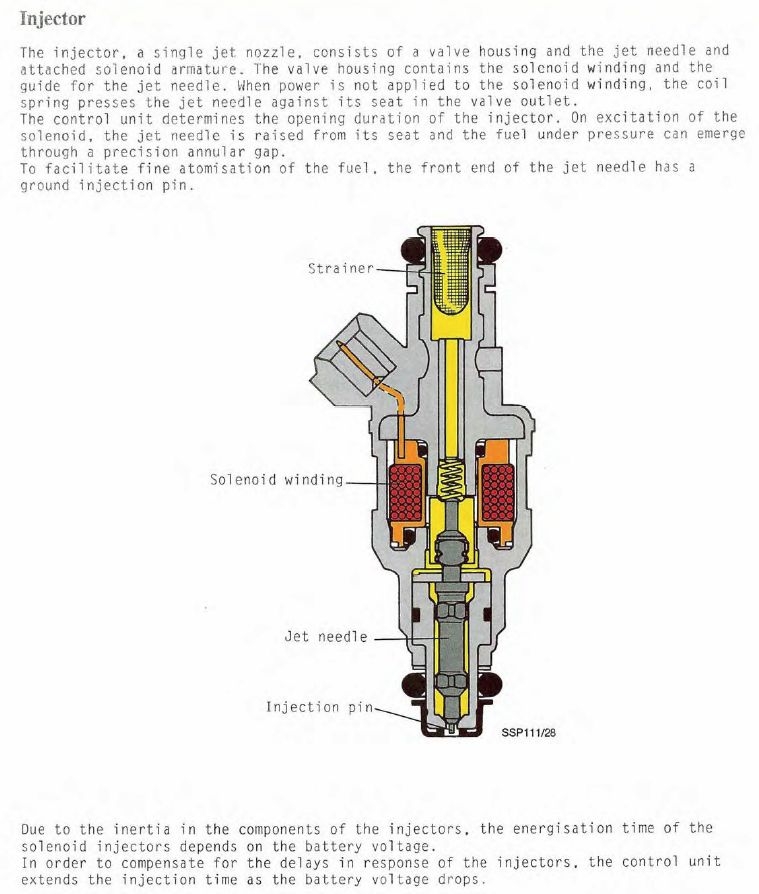

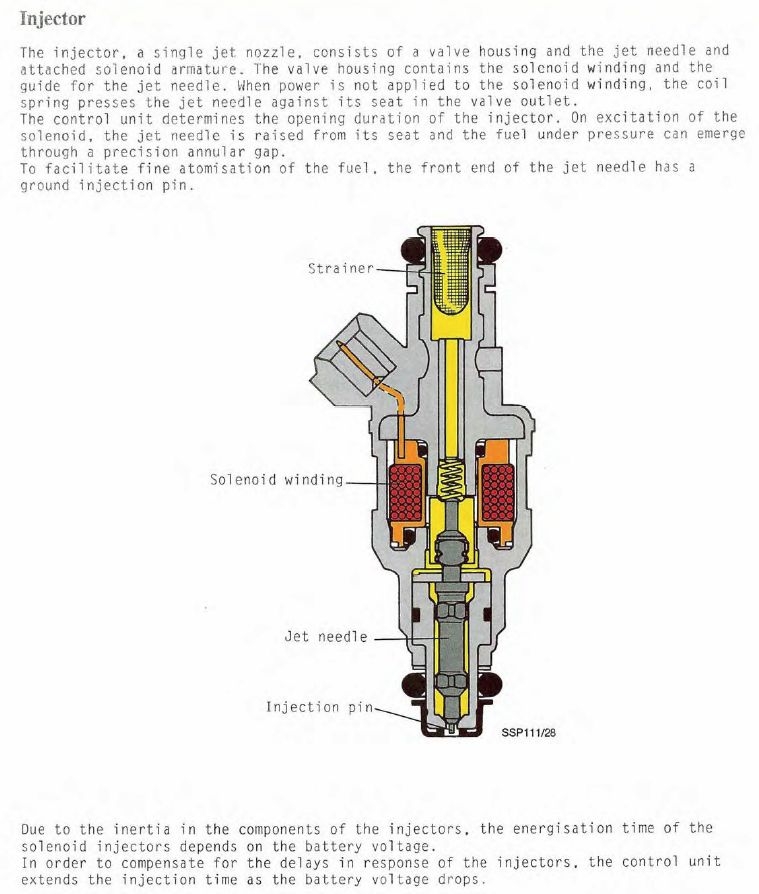

Our cars use electronic fuel injectors that are controlled by the ECU as to when they are opened and for how long they remain open for a given load (RPM, boost) condition. Fuel injector action is as shown here:

The main parts of our injectors are the strainer, the solenoid, the injector pin, the seal and the nozzle, as shown here:

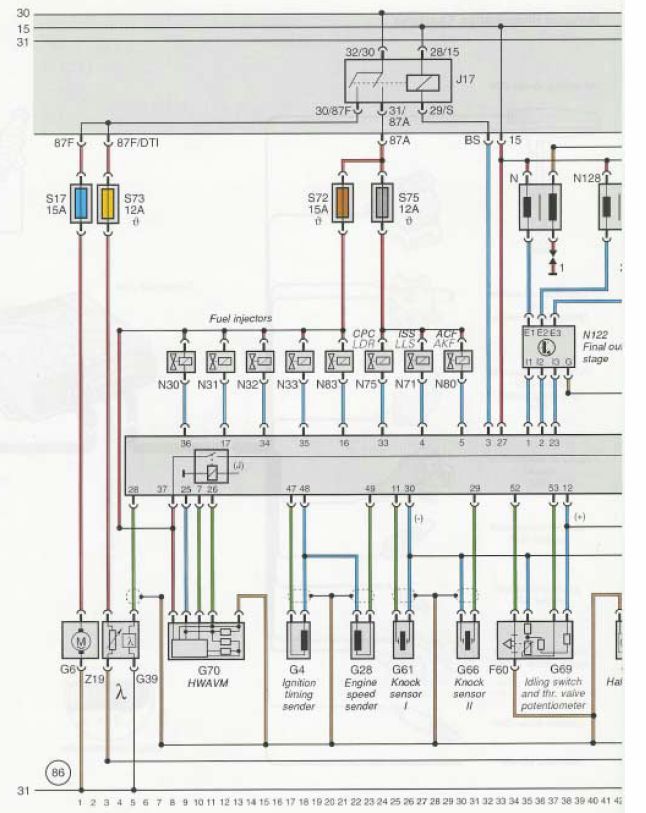

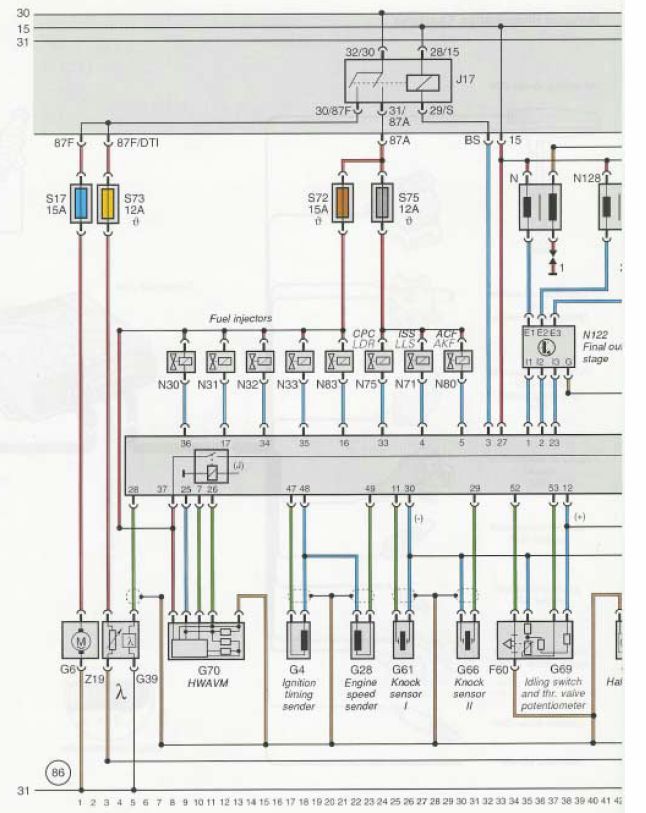

The injectors are energized by the

J17 Fuel Pump Relay (via a 15 amp fuse (S72)) and controlled as to timing of the injector opening and duration of that opening by the ECU, as shown here:

As you can read, keeping your charging system and battery in proper working order is important to injector performance.

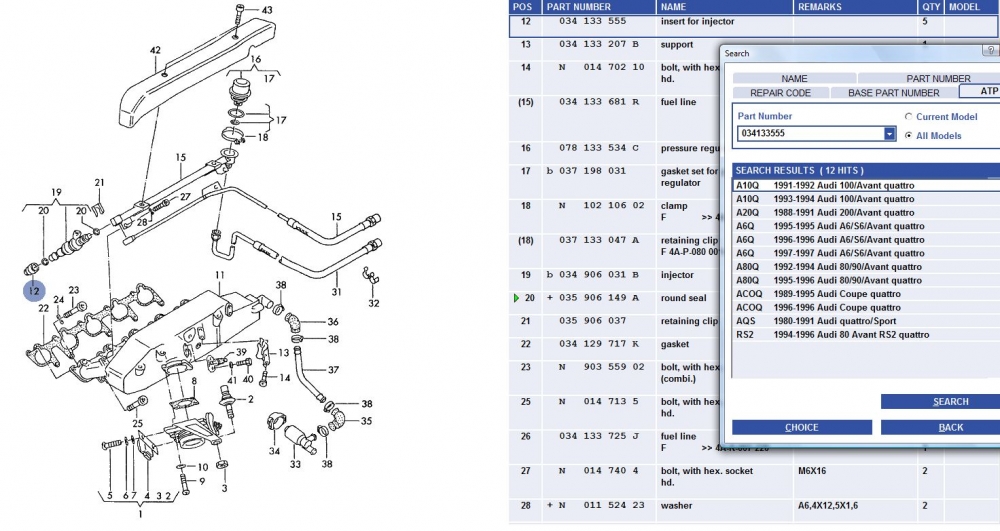

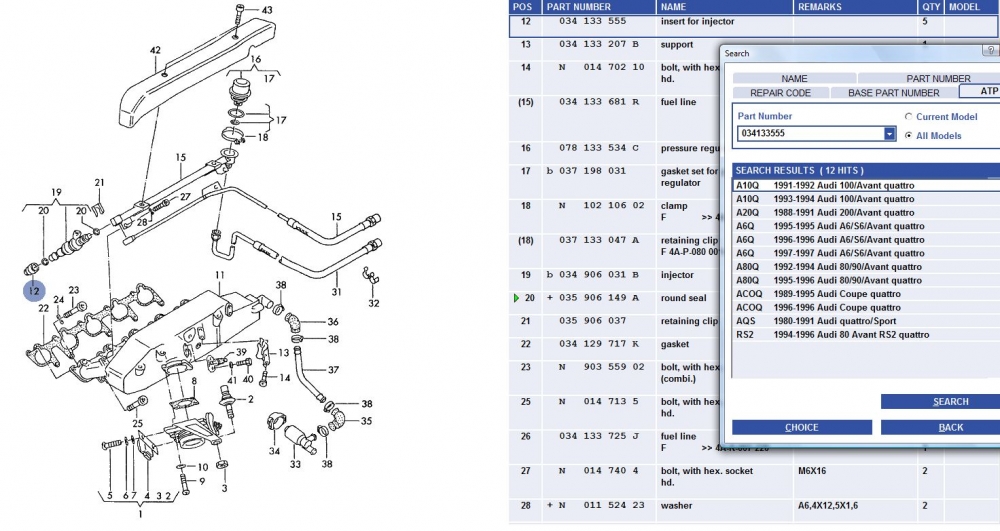

The 3B(200 20vt, early S2), AAN (UrS4/6) and ABY(later S2),and ADU (RS2) engines all use different injectors. It is common for 3B and AAN and ABY owners to upgrade to RS2 injectors when going above 280 hp. Here is some injector info, including rated flows

3B: Audi PN 034 906 031, Bosch PN: 0 280 150 737

AAN and ABY: Audi PN 034 906 031 B, Bosch PN: 0 280 150 951, flow:

280 cc/ min @ 3.0 bar

315 cc/ min @ 3.8 bar

323 cc/ min @ 4.0 bar

361 cc/ min @ 5.0 bar

ADU: Audi PN 034 906 031 F, Bosch PN: 0 280 150 984, flow:

360 cc/ min @ 3.0 bar

405 cc/ min @ 3.8 bar

416 cc/ min @ 4.0 bar

465 cc/ min @ 5.0 bar

Keeping your injectors in top performance does include the potential for out of car testing, cleaning and potentially refurbishment (seals and pins, etc). Here is one example of the improvements after injector cleaning:

Injector Cleaning Video

The injector inserts were not widely used (see diagram below (item 12) for cross-listing) but the O-rings (item 20) are widely available:

This will be on the exam