Our AAN-engined UrS-cars have a tandem vane pump that provides the fluid pressure to drive both the

power steering system and pressurize the

power brake system. This pump has two parts, a high pressure piston pump for the power brake system (to pressurize the brake pressure accumulator (aka "the Bomb")) and a low pressure vane pump for the power steering system. This pump is driven by

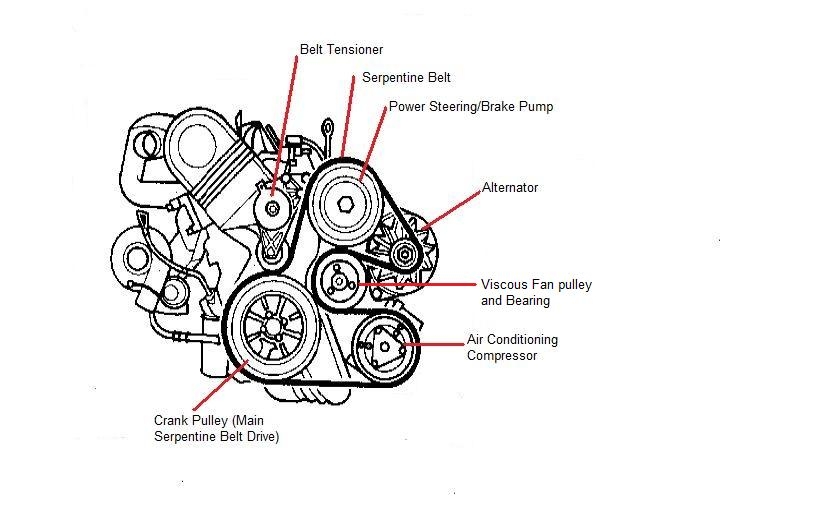

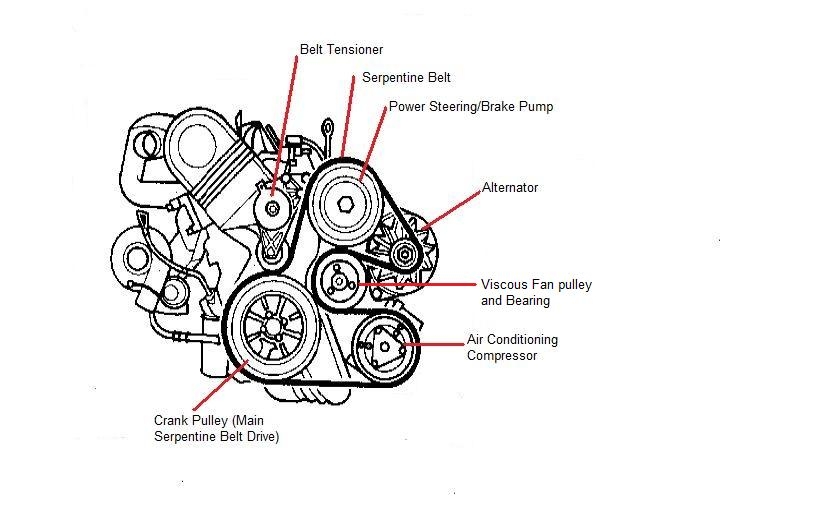

a very important serpentine belt, as shown here:

Here is the pump in its native habitat:

Photo courtesy of Steve M.(Boxflares) from his

PS Pump R&R DIY

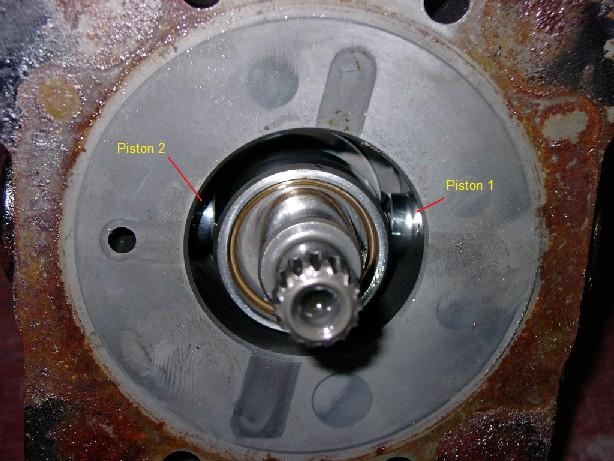

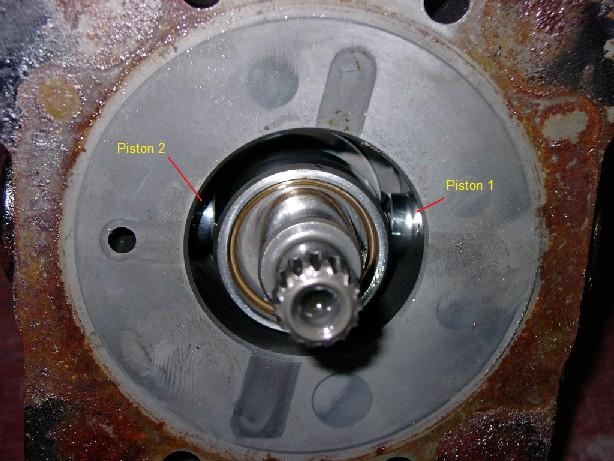

Internally, the high pressure piston side looks like this:

In general, vane pumps work like this:

The hydraulic power for the steering is provided by a rotary-vane pump (see diagram below). This pump is driven by the car's engine via a belt and pulley (our serpentine belt). It contains a set of retractable vanes that spin inside an oval chamber.

As the vanes spin, they pull hydraulic fluid from the return line at low pressure and force it into the outlet at high pressure. The amount of flow provided by the pump depends on the car's engine speed. The pump must be designed to provide adequate flow when the engine is idling. As a result, the pump moves much more fluid than necessary when the engine is running at faster speeds. REFERENCE:

How stuff works

The low pressure, vane pump, side of our tandem pump looks like this:

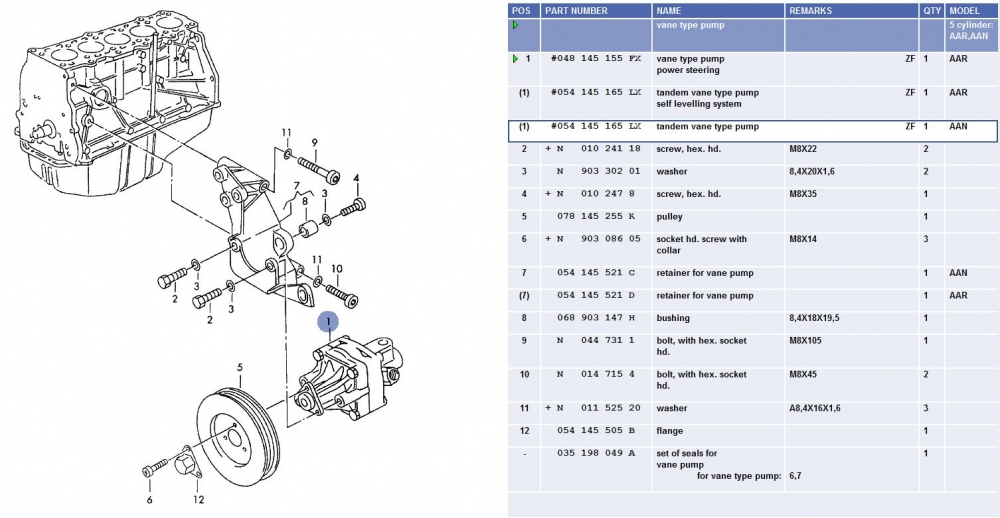

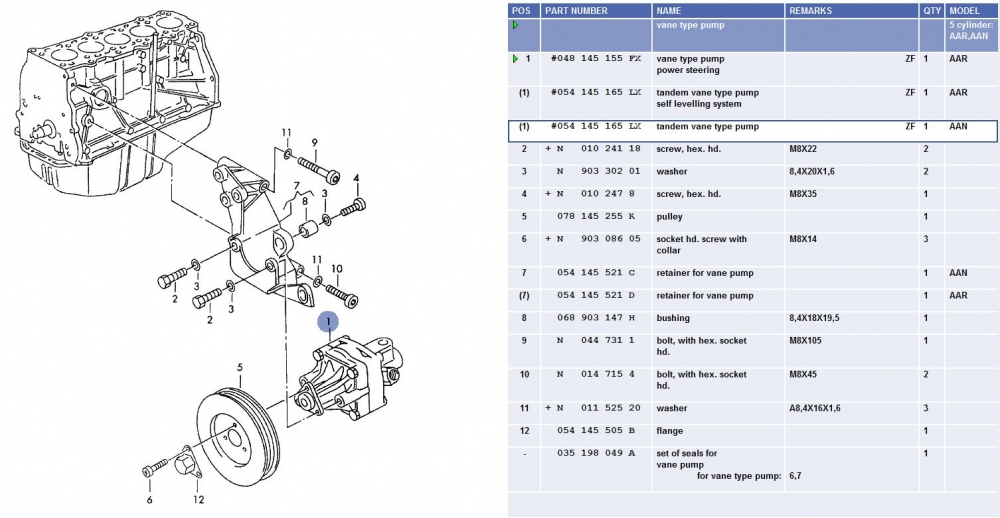

Our particular tandem (dual channel) vane pump is as shown in this diagram:

Parts that can be replaced include the pump seals (035198049A as listed above, beneath the Item 12 info) and the X-plug and its special O-ring (026145541):

Graham (from Queensland on the S2 forum) has documented the disassembly of these tandem pumps, as shown

HERE