Secondary Air Injection

|

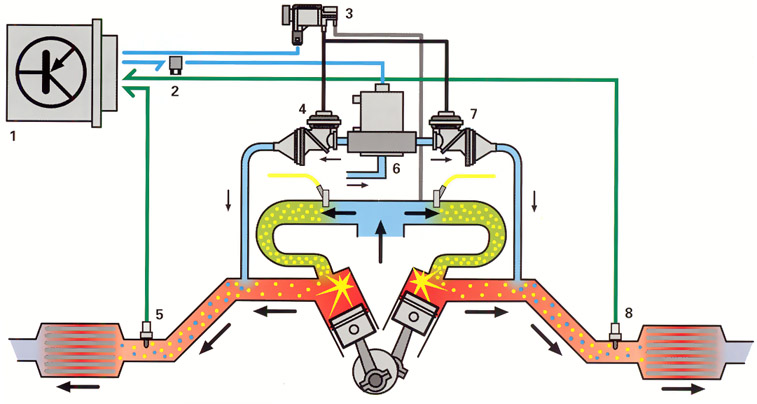

1 Engine Control Module

2 Secondary air injection pump relay 3 Secondary air injection valve control, Bank 1 and 2 4 Multi valve, Bank 1 |

5 Oxygen sensor, pre-cat, Bank 1

6 Secondary air injection pump 7 Multi valve, Bank 2 8 Oxygen sensor, pre-cat, Bank 2 |

A secondary air injection system was offered as an emissions control device in later revisions of cars with the MMS411A ECU (starting in late 1997).

General theory

The engine requires a relatively rich mixture for smooth operation on cold start. For this reason, the ECU operates in open loop mode with a fixed fuel map for the first 20 to 120 seconds of engine operation until the oxygen sensors have heated to operating temperature. Because of this, exhaust gases contain high levels of carbon monoxide and hydrocarbons after cold starts. The unburned hydrocarbons could be further oxidized, except there is no oxygen left after combustion. By feeding air into the exhaust manifold (secondary air), CO and HC are oxidized through afterburning at temperatures over 600°C to form water and carbon dioxide. The exothermal reaction also increases the exhaust gas temperature, which warms the catalyist more quickly.

To achieve efficient warmup operation, a high secondary air flow rate must be achieved within the first few seconds of engine startup, and the air flow rate must be maintained until oxygen sensor control is in operation. Air flow is maintained by an electric air pump (6). Once the oxygen sensors and catalytic converters have reached their operating temperatures, valves (4, 7) cut off the secondary air flow.

What the ECU monitors

An activated secondary air injection system leads to an increase in oxygen content in the exhaust (air flow from the secondary air pump). This increase is noted by the ECU by reduced pre-cat oxygen sensor voltage. If the engine management system gives the opening signal to the secondary air injection vaolve and switches on the pump, an extremely lean mixture should be found at the pre-cat sensors if the secondary air system is operating correctly.

|

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||