First a quick disclaimer that nothing I've done today is required and some of it even discouraged. I list it all for information purposes only and anyone may put as much of it as they want into use. If it works long-term with great results I'll take credit. If it falls apart, goes south in a banana boat you never heard of me. Gottit?

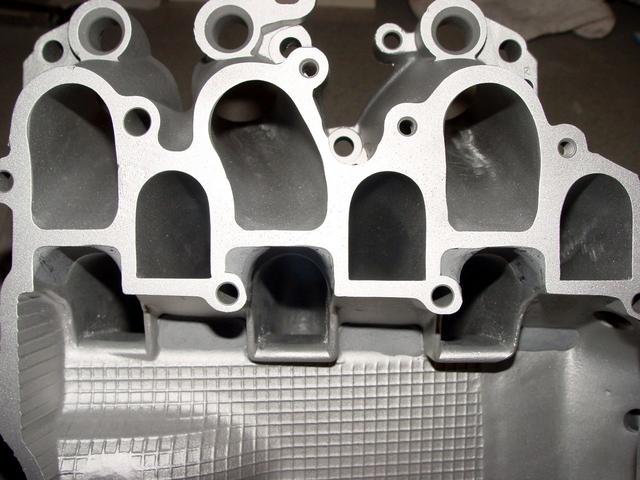

Here's the manifold with almost a pound of QuikSteel epoxy putty in all the little nooks and crannies. I filled the deep valleys between primary inlets in the bottom of the lower half. The tops of the primary inlets have also had the tight "dead-air" nooks eliminated with epoxy putty. Then sanded into the shape of the rounded inlet. Easy to do as the walls there are rough and give a good 'tooth' for the epxy to cling to. Essentially just pack the crap out of it then a 1" 120 grit flapper wheel makes short work of shaping it to match the runner below.

Entire lower half of IM has been media-blasted inside and out and deep into all the runners with plastic media so no risk of silical contamination getting into the engine internals. This too is an optional procedure but I wanted it to give the Glyptal some added tooth and to make everything look more even/uniform than it actually is.

I ran a sample piece over to a friend of mines yesterday to use his surface comparator to find out what "grit finish" my media would impart on the surface. Comparator shows 134 grit-comparable.

I'll try to get the Glyptal on later today and let it bake in the curing oven overnight at about 200F for 4 hours then 250F for an additional 8 hours. It may not happen today cuz the bars beckon tonight and I want to do this all at once and not piece-meal. Surface finishes are seriously finicky about drying/curing procedures.

But you guys will be the 2nd to see it whenever it gets done