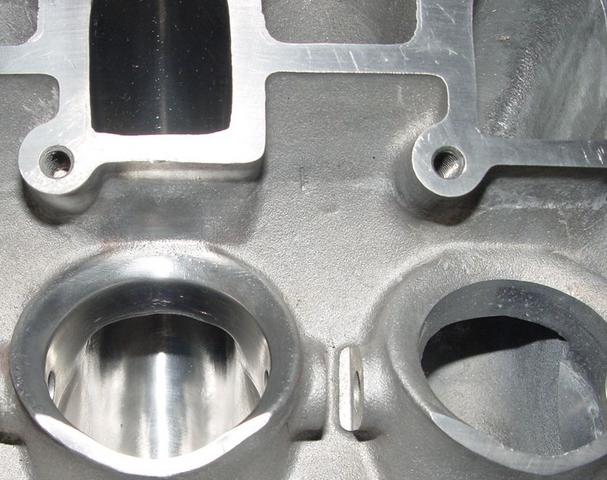

I've completely finished one runner in the intake top half. This is the runner from the other day that showed "before/after" shots. Most people wont be doing the area just inside the butterfly ports but since it's such a large hole it's the best shot I can take that shows what a finished runner looks like when honed and polished. Also notice that the area inside the secondary inlet, just below where the far side butterfly plate would rest in the closed position, has been dressed into a radiused and contoured transition into the runner area in stark contrast the the razor sharp edge in the adjoining runner. Left as they are that would be HUGE HUGE impediment to smooth transitions of air, volume and velocities moving thru that area... MUCHO turbulence! Additionally the small bell-mouth secondary inlet has been polished. This is something everyone will be able to do with the polishing kit as the butterflies needn't be removed to accomplish it. Small benefit but it all adds up! If you're gonna be a dog, why be a chihuahua!?!

At this point I'm going to back away from recommending any other honing or bore finishing tools than the flapper wheels." I experimented last night with just the flapper wheels and find with the right grit and collet extensions there's just no reason to use anything but the flapper wheels. The 3 & 4 flap medium and small self-centering bore hones work fine in straight sections of tubing but chatter uncontrollably when trying to negotiate a curve inside the runners. I'm afraid for the newbies at this they are just a little too hard to control and risk ruining some work in the intake or breaking someones die-grinder. The small flapper wheels will do it all quickly, easily and are so much more forgiving to work with.

The polishing tools showed up yesterday but I havent gotten a chance to do a layout and picture session with them yet. Sometime over the weekend I'll do that. But as you can see from the picture I'm still as enamored with them as I was when I tried a sample of them early last week.

This weekend I'll work more on the intake and try to come up with an educated guess as to how many of each honing medium we'll need for this. And I'll try to do it in such a way that any kit I offer will have enough honing tools and extensions to do the entire manifold without too many unused spares lying around afterwards. I was able to hone and polish this runner with various extension in it's entirety from the left side of the manifold to the right with no missed spots in it's length. That won't be possible on the lower half of the manifold however we can get between 85% & 90% of it.

I'm now thinking closer to a $100 kit will cover it and leave plenty room for a few EGR 10mm flexhones and come in under my original $175 budget for this stuff.